Hello,

today i received some fun stuff:

I delidded already a couple CPU

(3770K/6700K/7700K/13900KF/14900KF/14900KS and some more for my friends)

So i think at least i know what i´m doing...

But i was still careful and before i sacrify my 9950X3D i´ll

gave it a shot on my 7600X3D.

and probably this was the best decission i made in the last months:

this is what the I/O die now looks like:

![]()

here is the total of the delidded CPU:

![]()

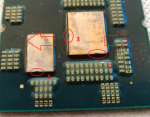

you can clearly see damage in the marked spots:

![]()

Spot 3 could be from the delid process but for 1 and 2

I have no explanation.

The delidder moves that way:

![]()

Did anyone of you discover the same or a similar issue with deliding?

today i received some fun stuff:

- Delid Die Mate

- AMD Mycro Direct Die Pro

- Conductonaut extreme

- some tubing and new fittings

I delidded already a couple CPU

(3770K/6700K/7700K/13900KF/14900KF/14900KS and some more for my friends)

So i think at least i know what i´m doing...

But i was still careful and before i sacrify my 9950X3D i´ll

gave it a shot on my 7600X3D.

and probably this was the best decission i made in the last months:

this is what the I/O die now looks like:

here is the total of the delidded CPU:

you can clearly see damage in the marked spots:

Spot 3 could be from the delid process but for 1 and 2

I have no explanation.

The delidder moves that way:

Did anyone of you discover the same or a similar issue with deliding?