Falkentyne, Thank you for answering me. This is very important to me.

I will now try to respond to your messages one by one.

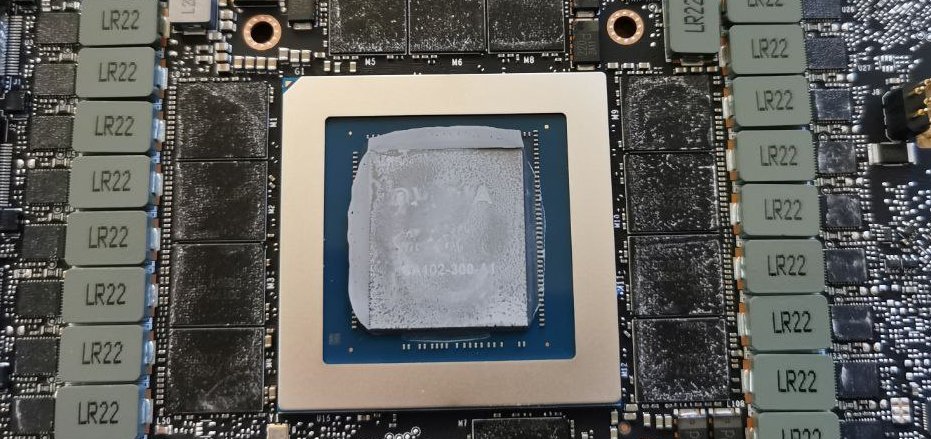

I applied TFX crosswise, then carefully spread it over the surface of the chip. Obviously, I didn't apply it enough, judging from your follow up photo.

I used Gelid Extrime 1.5mm thermal pads on the VRAM and Gelid Extrime 2.0mm on the VRM. Under the backplate I used Gelid Ultimate 1.5mm gaskets. All in all, I used everything you advised me earlier.

I used to think that thermal paste smoothed out the irregularities of the substrate and crystal, so I applied it in a thin layer. But after seeing you apply thermal paste, I was a bit surprised.

Do you really need that much thermal paste?

Before I answered you, I went to a friend's house. He also has a 3090FE. He doesn't use it for gaming. Four months ago I replaced his stock thermal pads with Thermalright odyssey 1.5mm. The thermal paste used was the simplest, no name. I went in to see what his GPU and GPU Hot Spot temperatures were under load. We ran both CP2077 and FurMark. And this is what I saw after 15 minutes of running and playing, the delta did not exceed 14C. GPU temperature was 75C, hot spot was 89C, memory temperature was 95C. And this despite the fact that the graphics card has been running 24/7 at 100% load for the last four months

To say I was surprised is nothing to say. What could it depend on?

The graphics cards are the same. The only thing that confuses me a bit is the issue date of my card (there's nothing wrong with that), but what the Z-V3 engraving means is the question. I highly doubt that Nvidia will make changes to the steam chamber design. Anything is possible, though.

Well, now I'm going to try applying thermal paste like you showed in the picture. I will replace the thermal gaskets with new ones similar to the ones I had.

I read your post somewhere that said not to overtighten the GPU mount plate. Is this true or not?

I tighten it all the way down.

After I get everything assembled, I'll report back.

If you have any other thoughts, post them.